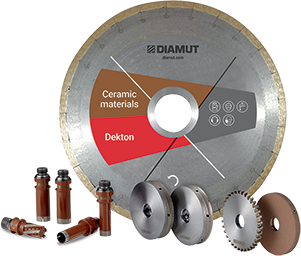

Giving shape to large sizes

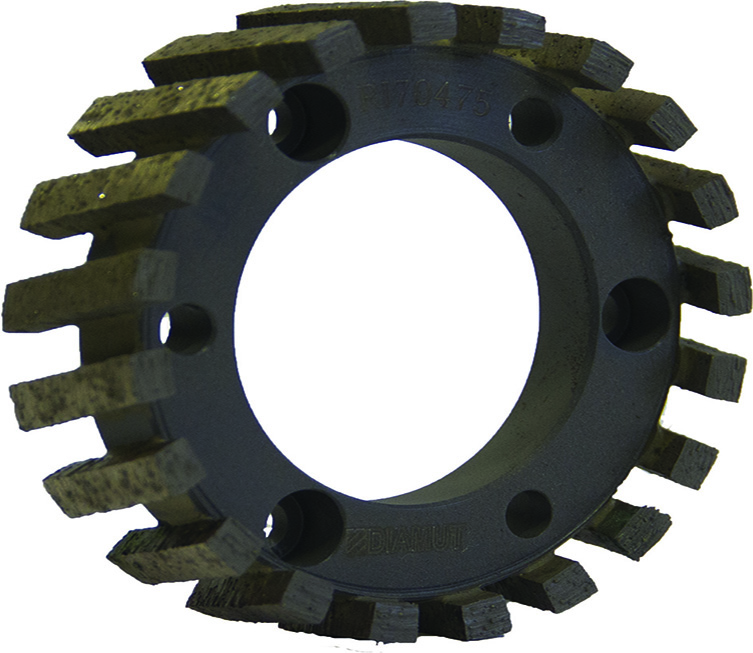

The Diamut range of grinding wheels for recesses is ideal for shaping any block of material, whether marble or granite.

Language

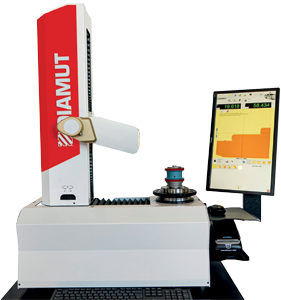

Tools designed to guarantee optimum results.

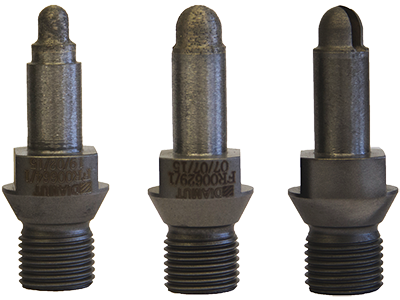

A series of sintered, electroplated tools for pocketing; they can be used with an extendible support. For all numerical control machines. A series of grinding wheels for machining Dekton is also available. Refer to the "Tools for Dekton" section.

Limit-free pocketing

There's an electroplated series for use with marble, featuring a range of diameters from 50 to 150mm. For granite, Diamut offers these diameters and also a selection of fretted wheels for major removal operations. All the grinding wheels can be combined with extensions of different lengths, according to machining requirements.

Stubbing wheels for high removal Granite and Engineered stone

Standard segment for Granite and Engineered stone

VIPER type - Stubbing wheels for granite and sintered materials

Electroplated stubbing wheels for Marble

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil