By switching from conventional grinding wheels to Diamut’s game-changing Hyper-speed wheels, glass fabricators can expect to halve their machining time whilst producing pieces with consistently satin smooth edge profiles.

Why vertical?

Vertical CNC machining centres are popular in the glass industry owing to the benefits they offer in terms of set-up and handling. Vertical loading eliminates the table preparation required by horizontal machines and makes it easier and faster to handle and load the glass. In addition, vertical machines occupy a smaller footprint than their horizontal counterparts, freeing up valuable floor space.

Introducing…VERTMAX

Intermac’s offer for vertical machining applications is the VERTMAX series. This features a patented system that enables automatic positioning of suction cups on the work piece, maximising productivity by reducing table set-up time to zero. VERTMAX is ideal for performing precision edge grinding and polishing operations on glass sheets used in shower cubicles, display cases, cupboard doors, furniture, household appliances, vehicle windows, and more.

Creating an edge

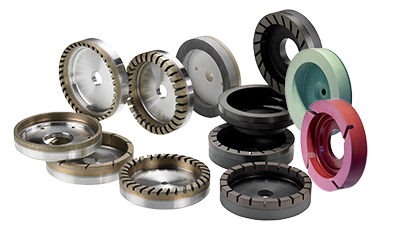

On a vertical CNC machine, 150mm diameter grinding wheels are used to create edging profiles such as a pencil edge and flat & arris. The sheet passes through two or three (depending on the degree of finish that is required) sets of wheels with a progressively finer grit prior to final polishing and finishing.

Diamut, Biesse’s tool manufacturing division, in synergy with Intermac, has quite literally reinvented the wheel.

Unique in the marketplace, Diamut’s new Hyper-speed grinding wheels have the potential to dramatically improve the performance of vertical CNC machines. Glass fabricators can effectively double their edge processing speeds by upgrading to this innovative new wheel design.

Profile engineering

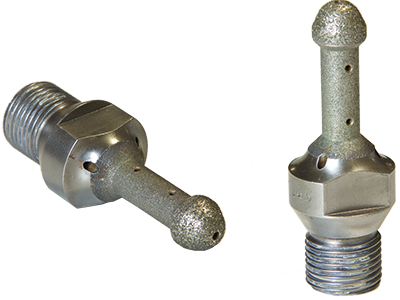

The key to this quantum leap in productivity lies in the profile design. The new ’first pass’ wheel (for coarse grit grinding) incorporates a plastic filler between the teeth where there is space on a traditional segmented wheel. This simple design enhancement has a huge impact on finishing quality, productivity, and component lifespan. Diamut’s new ’second pass’ wheel is similar in profile to a conventional slotted wheel, but uses a dedicated bond derived from automotive glass processing for enhanced performance and profile durability.

.png)

Lose the chipping

’First pass’ wheels are very aggressive, and a conventional segmented wheel usually generates some chipping on the edge of the glass sheet. With Diamut’s new design, chipping is reduced to a minimum, producing a far smoother finish than would be achievable with a standard segmented wheel. What’s more, less chipping equates to faster speeds; these new wheels can work twice as fast as standard wheels, delivering dramatic reductions in processing time.

Reaching a smoother finish on the first pass also has a knock-on effect for subsequent wheel performance - because there is negligible chipping on the sheet, the ’second pass’ wheel does not have to work as hard to remove as much material and can therefore work much faster.

Wheely fast wheels

When the two new wheels are used in sequence, this yields productivity gains that are impossible to ignore. When producing a flat & arris edge on a sheet of 6mm thick glass, the new wheels can work at machining speeds of up to 10m/min - that is roughly twice as fast as traditional wheels.

Using the new wheels, the amount of time spent machining each piece can be reduced by as much as 60% (on a 6mm glass thickness).

The new wheels are available for three glass thicknesses (6, 8 and 10mm) for flat & arris profiles, for machining monolithic glass. They are compatible with vertical CNC machines made by any manufacturer (not just the VERTMAX) and can be used in sequence for polished glass finishing or in a single pass for diamond finishing of low thickness glass.

Find out more about High Speed Wheels.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil