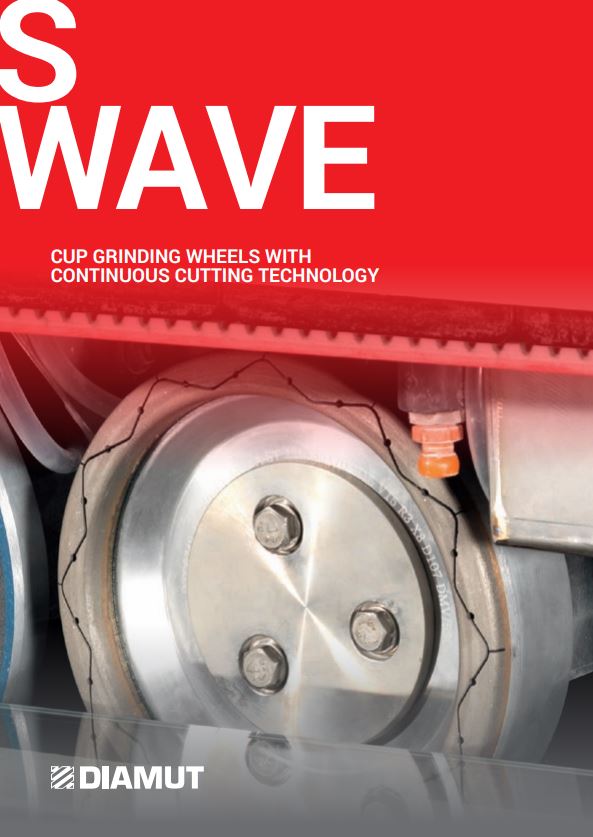

Wheel change intervals can be dramatically increased and finishing quality elevated with Diamut’s revolutionary new tooling for straight-line edging machines.

Straight-line edging explained

Straight-line edging machines are used widely in the glass industry for creating flat & arris profiles on work pieces with a straight edge. They can either be single line edgers, which only polish on one edge, or double edgers, which can process two sides in one pass. Larger operations may use a double edger line, which incorporates two sets of double edgers and a 90° transfer table - enabling all four edges to be finished in a single pass.

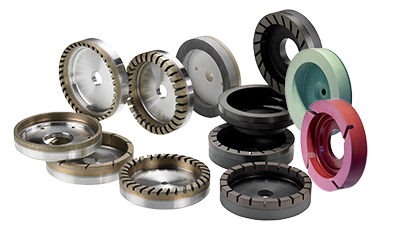

What all of these straight-line edgers have in common is that they use a series of abrasive cup wheels with diamond bonded to the metal around their periphery for preparing the glass prior to polishing. These wheels are consumable parts with a finite working life; when the bonded surface wears down to the point where the wheel is no longer able to grind effectively, the line has to be stopped so that the operator can change the wheel - a task that can take up to an hour.

R&D on a roll

Recognising that wheel changes were proving a major source of downtime for glass fabricators, engineers from Diamut, Biesse’s tool manufacturing division, went back to the drawing board. Working in synergy with Intermac, they developed an innovative new wheel, branded the SWave, that lasts three times longer than a standard segmented wheel. This longer life span is thanks to the combination of a new hard-wearing diamond alloy and the wheel’s sinusoidal (s-shaped) internal grooving profile.

Tough diamond

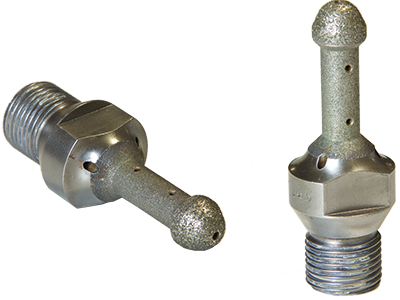

The new diamond bond on the face of the wheel works in several ways to increase the durability of the tooling: through its unique composition, the alloy promises increased sharpness, but at the same time, the bond is more refined and therefore less aggressive on the surface. This gentler interaction with the material not only extends the lifespan of the wheel but also results in a higher quality finish as chipping is minimised.

Facilitating the flow

The s-shaped grooving profile also contributes to a superior finish by facilitating the circulation of water during the machining process. This design is far more effective at expelling swarf and splinters than continuous rim geometries, leading to dramatic reductions in grinding splinters and ensuring optimum preparation of the surface for the subsequent polishing stages.

Laminated glass? No problem

A further advantage of the SWave wheel is that it can be used on both monolithic and laminated glass surfaces. Standard segmented wheels will often encounter issues when cutting laminated glass, due to the presence of the interlayer. Typically, plastic tends to accumulate between the teeth, impairing the wheel’s performance.

The new high performance diamond bond allows the SWave to cut through this multi-layered material with ease, whilst the enhanced water circulation around the wheel prevents it from getting clogged up with debris.

SWave is available with a diameter of 150, 175 or 200mm for double sided and straight-line edging machines built by any manufacturer.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil