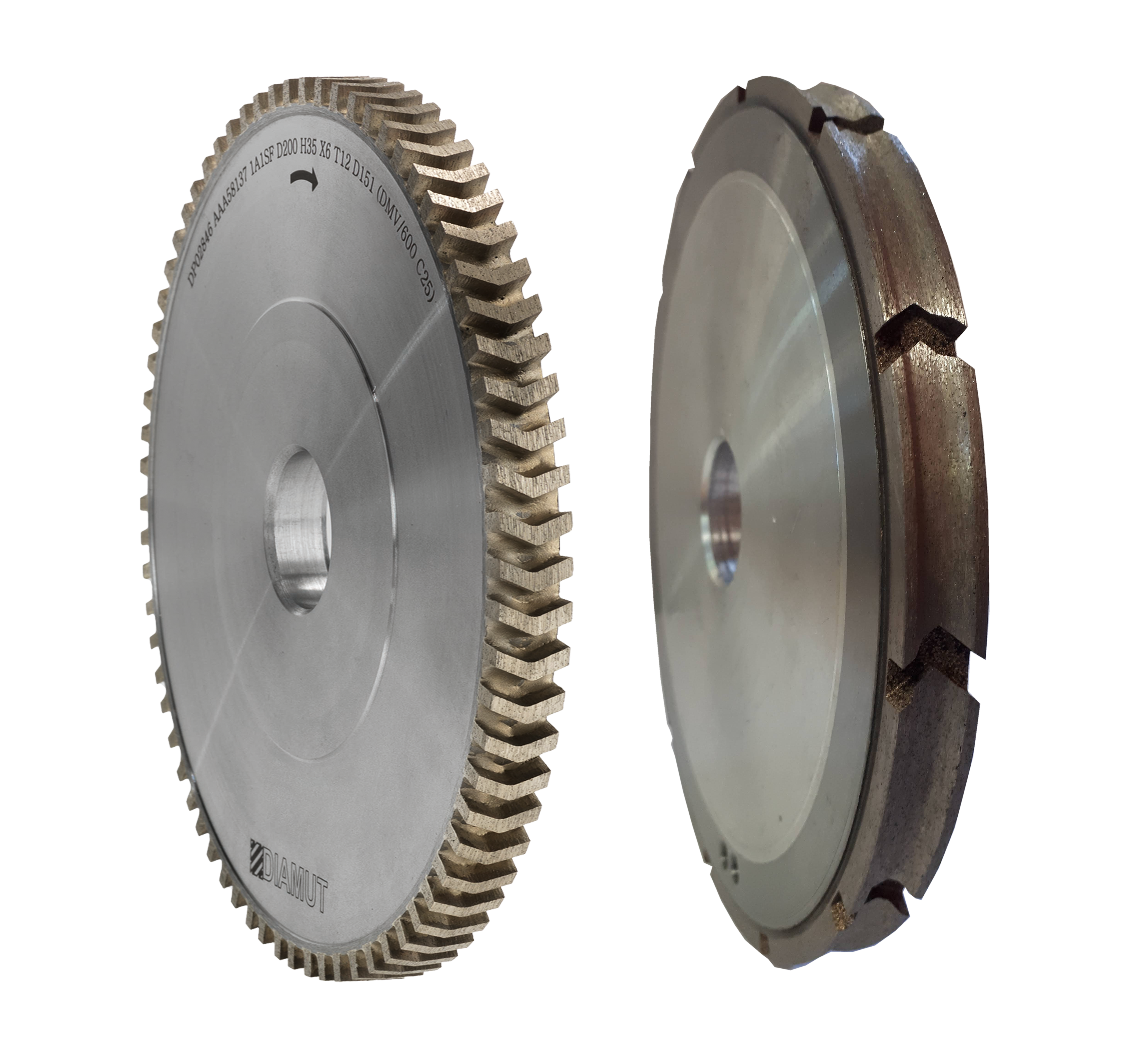

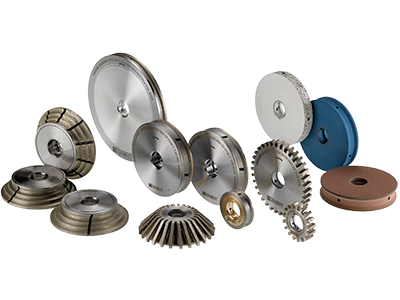

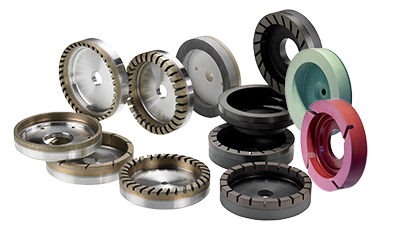

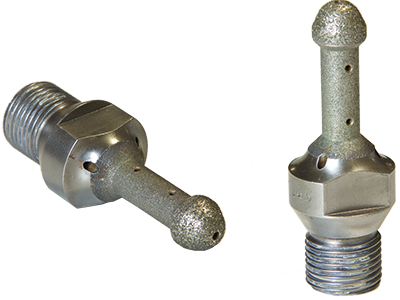

The CHEVRON20 high-performance peripheral grinding wheels guarantee reduced production start-up times, top machining speeds, optimum finishing quality, maximum performance, a long lifespan, and perfect shaping of the edges. Dedicated to the machining of laminated glass 33.2 - 1010.2 thick with a diameter of 200 mm, both segments and continuous rim. With various grains for a rough or high-quality finish.

This line is made both in sectors and continuous band in the different grits for raw finish and high quality.

In the sector version, the wheels have been made with a new geometry to facilitate the cutting of the plastic film without tearing it. The arrow shape ensures that the grinding wheel works centered on the glass and with the sharp tip against the glass.

Diamut has always been committed to research and innovation. This allowes to improve the type of cuts on the continuous band wheels. Thanks to the open ended profile, and not closed as in the previous line, and with a wider width, this line of peripheral wheels guarantees a greater volume of the waste, allows a greater flow of the coolant avoiding the overheating of the grinding wheel and a rapid discharge of the removed material.

Thanks to all these features: optimization of the cooling, type of binder and geometry of the sectors to avoid the deformation of the grinding wheel at the plastic layer, we found excellent results of deformation and wear: after 1600 meters of work have shown a deformation of the external threads of the profile and not of the grinding wheel center. The CHEVRON grinding wheel processes a laminated glass as if it were monolithic glass!

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil