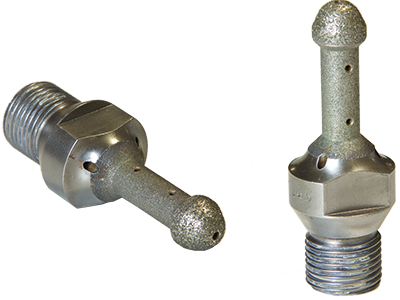

Helix tooling was such a hands-down success last year that Diamut America is giving it an encore run on their new Master One work center at GlassBuild America coming to Atlanta GA, September 17-19. The revolutionary new Helix drilling system can create holes with upper and lower integrated countersink on glass plates up to 19mm thickness, using a single CNC machine tool. The Helix tool is changing the direction of how work gets done by descending in a spiral movement, rather than vertically. It enters through the upper part of the tool, and the hole is ground in the glass instead of being drilled. After the initial hole is made, side grinding enlarges the hole up to the nominal dimension. Lower and upper countersinking corrects any possible imperfections. GlassBuild visitors can learn about how Diamut’s Green Arris wheels have been developed to achieve maximum performance for polishing on glass plates, processed with bilateral and straight machines. The product was developed through a collaboration between Diamut and Busetti that included polishing and durability testing.

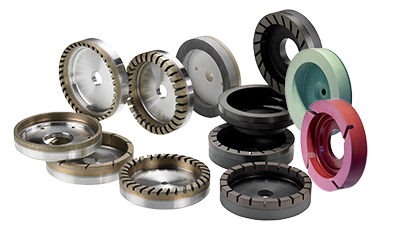

The Green Arris wheel, mounted with resin wheels from Diamut’s cup wheel range, has enabled more efficient processing times, while achieving a high quality clean bright consistant arris. You can also find out about the latest-and-greatest developments at Diamut’s new manufacturing facility, which debuted in March on the Biesse Campus in Charlotte. It marked the first time Biesse has ever opened a manufacturing facility on American soil. The new operation is now fabricating Italian-engineered Diamut diamond profiling wheels for glass, cup wheels for glass, stone and ceramic processing. It has effectively increased the company’s ability to respond to growing market needs in North America and to meet the expectations of Diamut customers worldwide.

Diamut also opened a North American tool redressing facility in Charlotte in 2018. It has succeeded in offering customers in the U.S. and Canada more timely and attentive customized support, faster turnaround time and reduction in shipping costs. Diamut expertly matches the profiles of wheels customers send in, reshapes them and redresses them to be like new. Both the new manufacturing and redressing facilities further demonstrate Biesse’s determination to continue its commitment to serve customers in North America closer to home.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil