PIONEERING INNOVATION

The term "sintered" refers to materials obtained from the mixing and subsequent compressing (to form sheets) of raw materials such as silicon, quartz, aluminium and so on, with a high degree of purity, subjected to production cycles at high temperatures and pressure levels. The aim of these processes is to obtain chemical bonds between the raw material particles (the "sintering" process), forming low-porosity sheets with excellent properties in terms of colour, dimensional stability, resistance to mechanical strain, abrasion, marks, heat, scratches and chemical/atmospheric agents.

Language

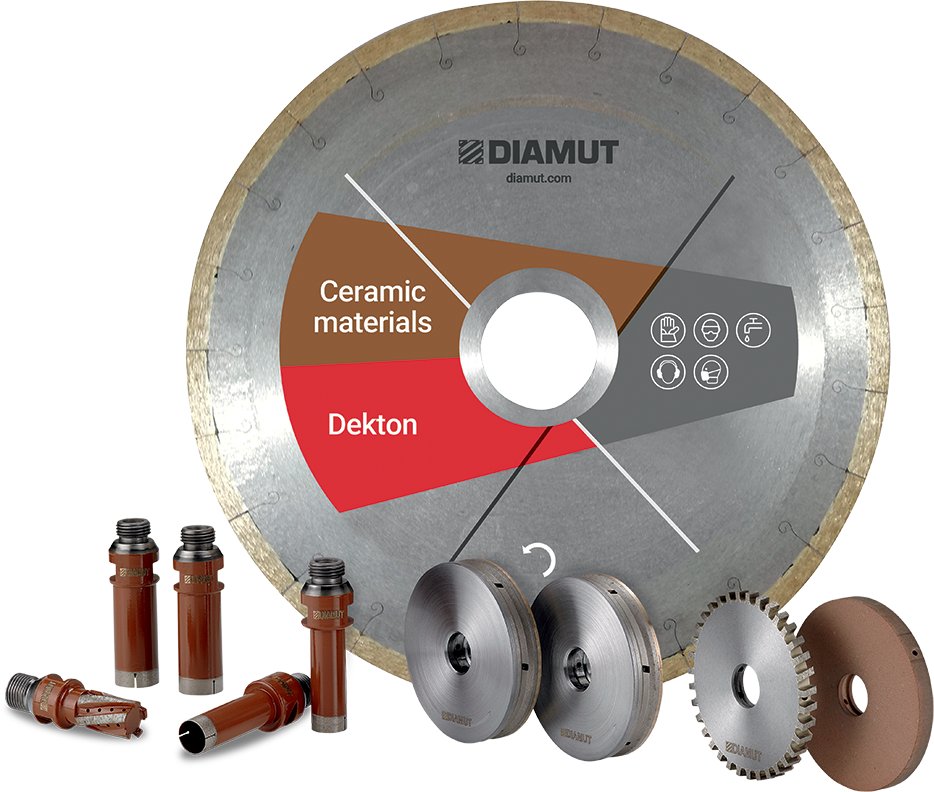

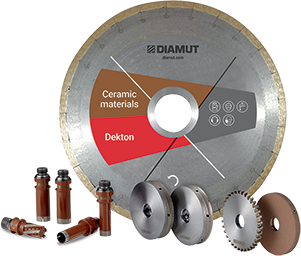

Tools for sinterend materials

TOOLS FOR SINTERED MATERIALS

Tools for sintered materials

INNOVATION FOR THE NEW MATERIALS

20% reduction in the production area required, as well as a 70% increase in productivity compared to a normal combination.

Comby lines are combined lines that were introduced onto the market by Intermac for high productivity cutting operations, and are the result of a clever combination between the Genius CT-A and CT-Red cutting tables (for float glass cutting) and the Genius LM and LM-A tables (for laminated glass cutting): two automatic lines, one for float glass and one for laminate, for perfect integration even in smaller spaces.

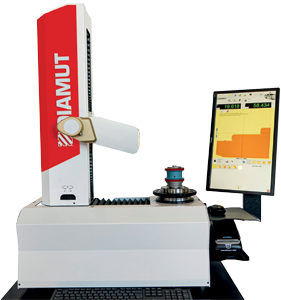

MILLING CUTTERS AND DRILLS

HIGH-PRECISION MILLING AND BORING

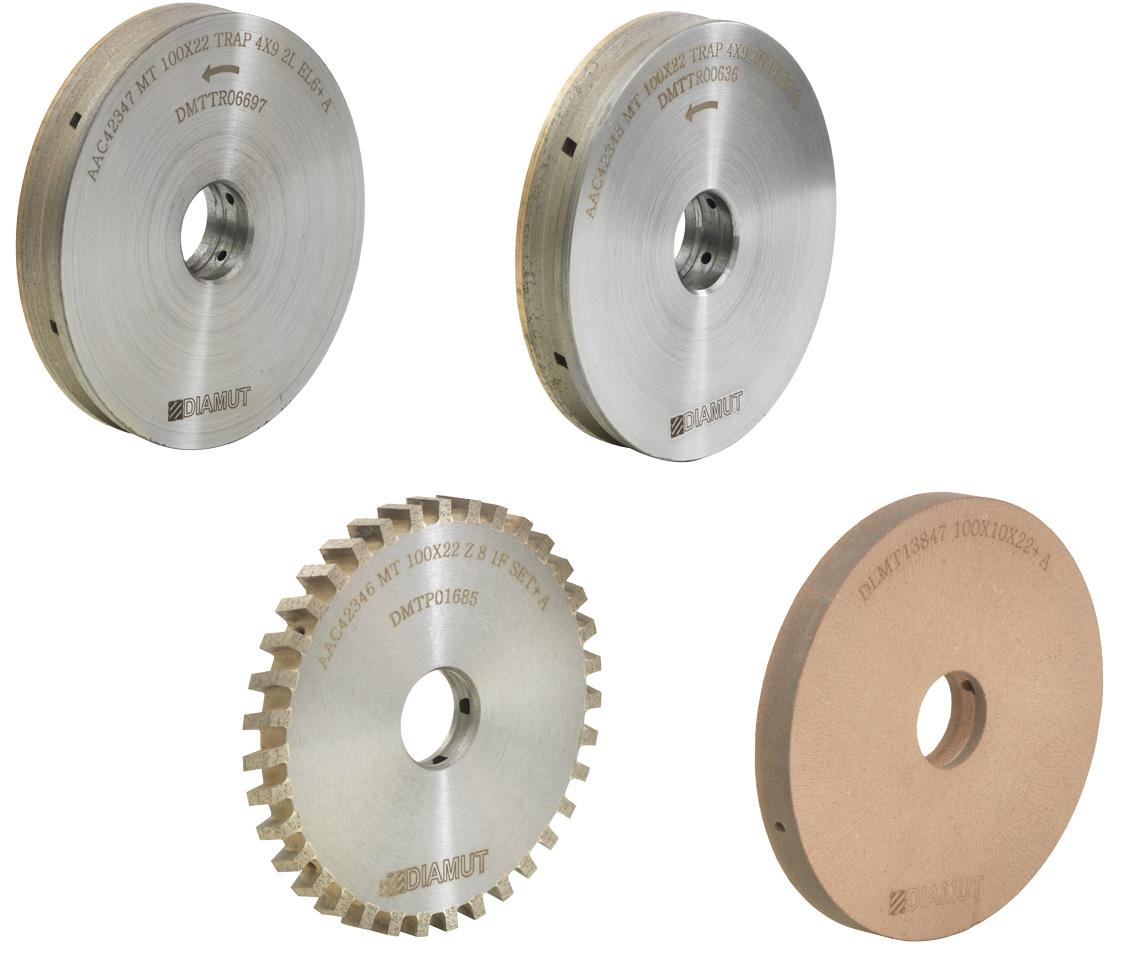

Each version is available with various binders and grits; This ensures the perfect balance between tool durability and perfect finish quality.

PERIPHERAL DIAMOND GRINDING AND POLISHING WHEELS FOR CNC

LIMIT-FREE PROFILING

To obtain profiles of every type using CNC machines, the Diamut tool range includes 3 diamond wheels (segmented and continuous band) and 1 polishing wheel. There are various profiles available in the catalogues, but others can be tailor-made to meet customers' specific needs.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil