Language

June 30, 2019

Natural Stone Institute

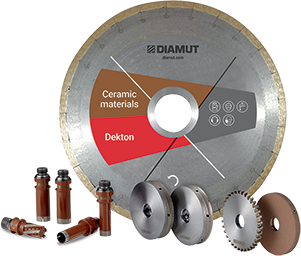

s industry experts already knew, quartz started taking a lot of market share 5 or 6 years ago. The trend continues to grow. “That’s a very good thing for the big manufacturers,” said Peter Hauser, Diamut North America Sales Manager. “They love the popularity of quartz because it’s a material that reacts so consistently and works so well with Diamut CNC tooling.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil