PIONEERING INNOVATION

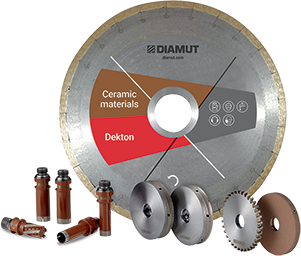

Dekton® is a material with extraordinary properties. The intelligent combination of raw materials and the latest-generation technological processes used in the production of Dekton® make it a very special product. Thanks to skills built up during its continuous search for new solutions for a constantly evolving market, Diamut has come up with a set of tools consisting of drills, milling cutters, peripheral grinding wheels and slitting discs.

Language

TOOLS FOR DEKTON PROCESSING WITH CNC

Developed in collaboration with Cosentino Group, the Diamut kit of tools for machining Dekton represents the very latest in Diamut's R&D in relation to the machining of synthetic materials.

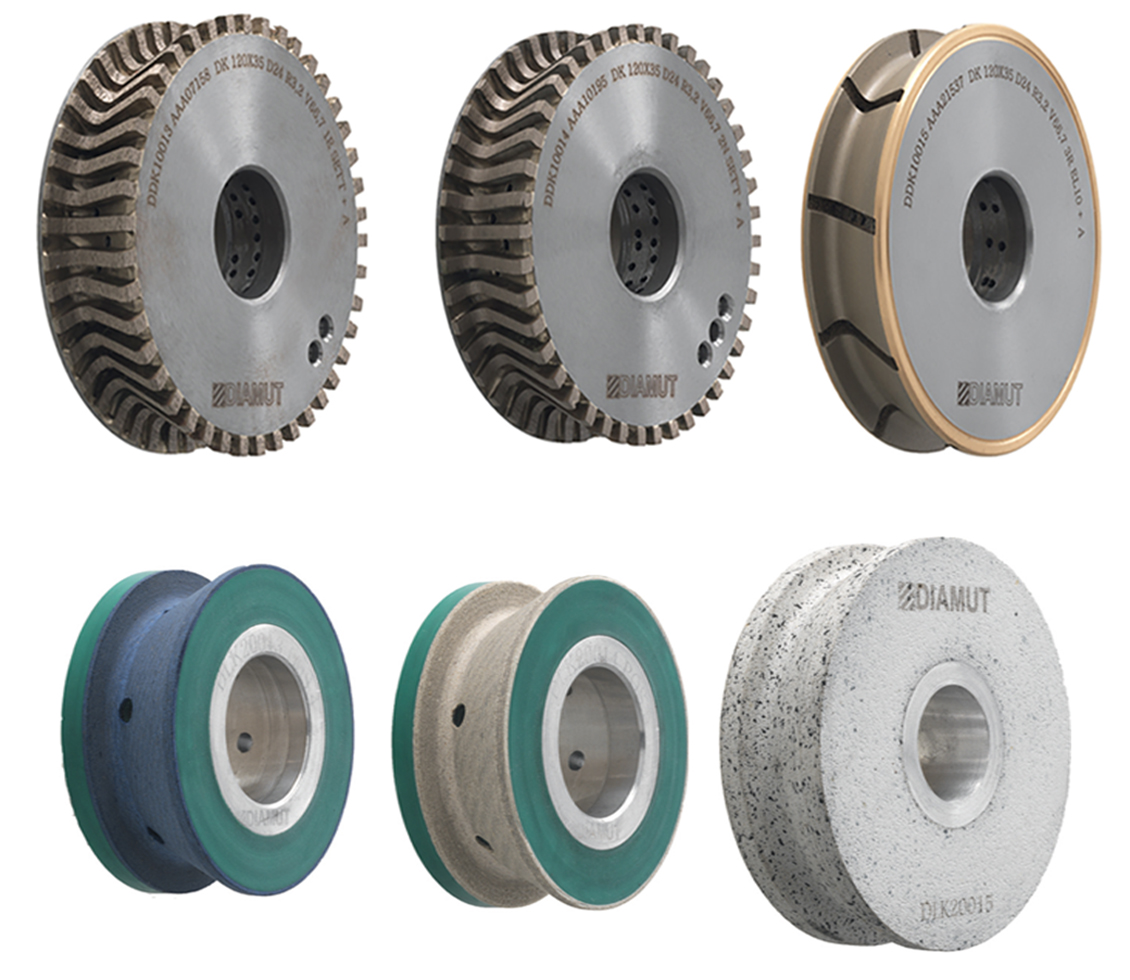

MILLING CUTTERS AND DRILLS

HIGH-PRECISION MILLING AND BORING

Each version is available with various binders and grits; This ensures the perfect balance between tool durability and perfect finish quality.

GRINDING WHEELS FOR THE INSIDE OF WASHBASINS – ½ GAS

TOP INTERNAL WASHBASIN RESULTS

L'usinage pour réaliser un intérieur d'évier requiert des outils précis. Le jeu de meules pour intérieur d'évier Diamut avec raccord de ½ " GAS garantit un finissage optimal en des temps réduits d'angles d'orifices d'évier ayant un rayon très étroit. Il se compose de 4 meules diamantées de différentes granulométries et raccord de ½ GAS (Ø 20 mm). Au choix, un autre jeu de meules lustrantes est disponible pour compléter l'usinage.

MILLING CUTTERS FOR FLUTES

MILLING CUTTERS FOR FLUTES

The last step of the procedure is usually the creation of the dripstone. Diamut has 3 milling cutters that produce a perfect series of grooves of the necessary width, depth and inclination on the surface of the washbasin. There is also a specific drill for the “top edge”, for finishing off the profile when the washbasin is at the same height as the sheet edge.

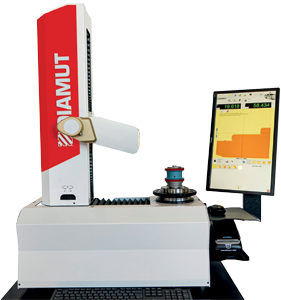

PERIPHERAL DIAMOND GRINDING AND POLISHING WHEELS FOR CNC

LIMIT-FREE PROFILING

To obtain profiles of every type using CNC machines on the inner part of the Dekton sheet, the Diamut tool range includes 3 diamond wheels (segmented and continuous band), 2 polishing wheels and 1 buffing wheel. There are various profiles available in the catalogues, but others can be tailor-made to meet customers' specific needs.

SLITTING DISCS FOR CNC

THE PERFECT CUT

Disc for cutting particularly compact material, with close-set diamond segments for the perfect finish; able to greatly limit the complexity of this type of surface. Diameters from 300 to 625mm.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil