5 Steps to the Stone Tools Redressing Process

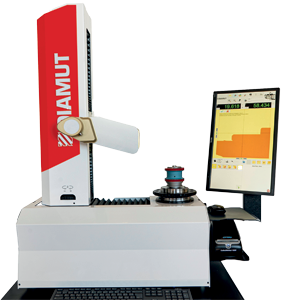

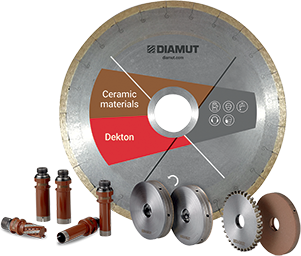

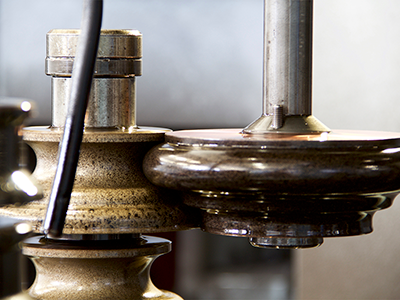

Diamut tooling is highly designed to achieve tolerances that are extremely tight. The tool redressing process requires extremely skilled operators using a sequence of precision, custom-engineered machines to match original tool profiles precisely.

If you would like to view the PDF version of this article, click here

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

Deutschland

Deutschland

España

España

North America

North America

Brasil

Brasil